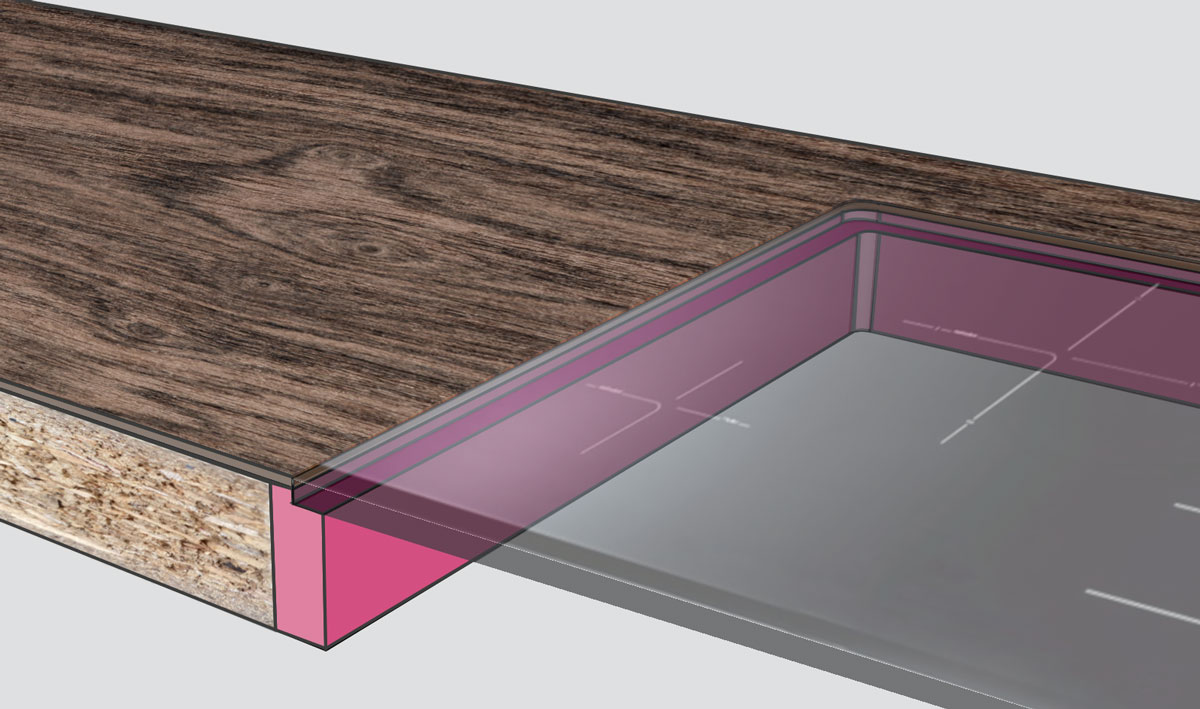

Flush installation in laminate worktops

True to size, without swelling – with casting resins from ebalta

For flush installation in laminate worktops, well-known worktop manufacturers in Germany have been using ebalta’s polyurethane casting resins for several years. To prevent the worktop from swelling on contact with moisture, the surfaces are sealed with the casting resin. After curing, the plastic can be processed like wood and cut to the exact size required. This creates the cast resin frame, which enables flush and dimensionally accurate installation in laminate worktops – and the interfaces are protected.

The ebalta casting resin systems of the 500 series are characterised by very good flow behaviour and are suitable for both hand and machine casting. The material can be flexibly adapted to individual customer requirements.

Does that sound interesting? Please contact either our sales partner or International Account Manager Darrell Cross or use our Request Form.