Your competent partner

with the sustainable plastics solution

Mission

To be the first plastics producer with sustainable individual solutions from prototypes to medium series. That is what motivates us, that is our path!

In order to live up to this mission, we are constantly increasing the use of resource-saving raw materials. We know our CO2 footprint, reduce it permanently and offset remaining emissions in order to be carbon-neutral.

Thanks to the excellent know-how of our employees, we are able to deliver 100% quality and offer our products at competitive prices. In order to fully satisfy our customers, we work in customer-oriented processes. We see ourselves as a fair partner and employer. We strive to achieve the maximum satisfaction of our employees and partners.

Product diversity and

individual development

With over 2,000 articles, we offer a wide variety of products for almost every application with polyurethane and epoxy resins.

Our research and development team is on hand with its deep technical knowledge to meet individual development requirements.

Uncomplicated processing

We guarantee a timely and uncomplicated processing of orders. Within Germany, we deliver our products within 24 hours.

This does not apply to ebablock®, which we deliver within 6-7 working days.

Strong team

Our regional sales managers are a strong team of experts with a lot of practical experience. They provide on-site advice throughout Germany.

Our product managers provide support in every project phase. Worldwide, we work together with technically competent international sales partners.

Service

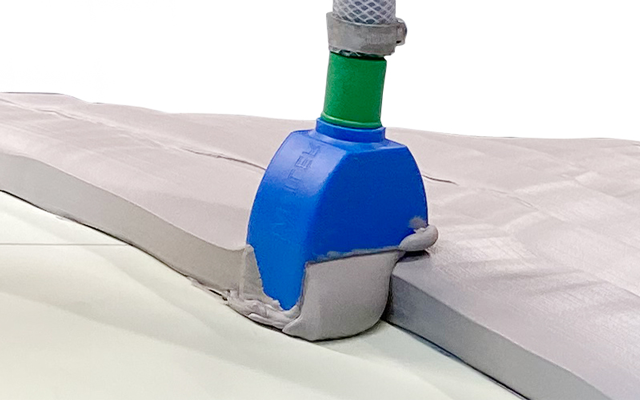

In order to design projects efficiently and economically, we take on the individual casting resin series casting of PU blocks. On the other hand, we apply our lay-up paste on site with our own machine.

Our services are rounded off by customer training on new and proven application techniques using practical examples.

Sustainability

In the case of new developments and on request, we offer the option of receiving the product in a carbon-neutral form.

Management of ebalta

We manage our company with a future-proof management system.

Thiemo Langer (Managing Director), Andre Neutzler (Managing Director) and Boris Langer (Partner)

Location

Since the company was founded, ebalta has been located in Rothenburg ob der Tauber, in the middle of Germany, in the middle of Europe. From our location, sustainable plastic solutions are offered quickly and reliably worldwide.

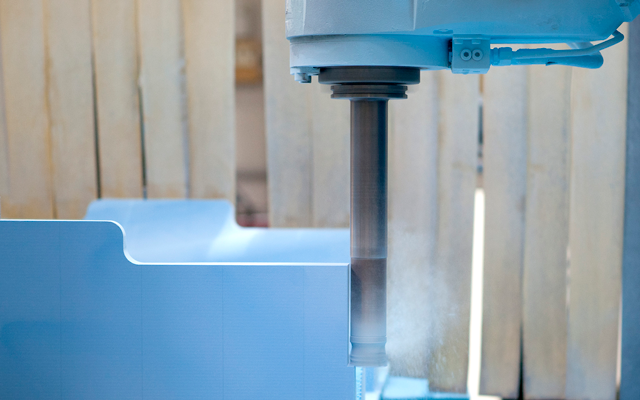

Modern equipment and production facilities

In order to offer 100% quality responsibly, we are constantly investing in production facilities.

On more than 25,000 square metres, we operate vacuum dissolvers and vacuum butterfly dissolvers with up to 1,000 litres volume, as well as 2- to 3-component casting systems for plates and blocks, among other things.

Our equipment offers the possibility of six-sided plate processing and our annealing ovens have room for model plates and individually cast blocks up to 8 m long with temperatures up to 200 °C and protocol printing. In addition, there are 2-component pasting machines for applying lay-on pastes as well as vacuum differential casting machines and low-pressure RIM 2-component casting machines.

In our development laboratory with all the latest technology testing and measuring equipment, chemists and chemical laboratory assistants develop according to your individual requirements. Our product managers have the opportunity to simulate a wide range of application techniques in the fully equipped technical rooms.

Milestones

During the 40 years of our company history we have reached important milestones.

2021

ebalta develops the first eco-friendly polyurethane for climbing holds. The carbon footprint is reduced and offset in all phases of the life cycle. The grips are made from a high quality and sustainable material.

2020

ebalta is certified as a carbon-neutral company! Since then, the aim of ebalta’s environmental policy has been to reduce the total CO2 emissions from the manufacture of ebalta products and to offset them by investing in climate protection projects.

2019

ebalta founds allHOLDS together with independent climbing holds manufacturers: A network to offer a wide variety of custom holds made from a high quality and sustainable material.

2018

After many years of development and testing, our epoxy resin boards for prepreg moulds are now available on the market.

2016

ebalta enlarges its production facilities for fabrication of ebaboard material density < 1 g/cm³.

2014

ebalta 40th anniversary: with a team of 110 employees then.

2012

Complete in-house production of ebaboard material density > 1 g/cm³.

2011

ebalta Innovation Award for sustainability and innovation capacity from the district of Ansbach.

2009

ebalta opens a new 2.200 m² production plant for manufacture of cast-to-size ebablock® and ebaboard materials with a

density >1 g/cm³.

2006

Further expansion of ebalta business with the opening of the 6th production plant.

2001

Construction of our ebalta headquarter building, right next to the warehouse and four production halls.

1999

Memorable ebalta 25th anniversary in “Reichstadthalle Rothenburg” together with customers and partners.

1998

Andre Neutzler, Boris und Thiemo Langer join the partnership of ebalta. One year later Andre Neutzler was inaugurated as the Managing Director.

1990

ebalta starts manufacturing! From the reproduction of products to research and product development.

1978 - 1988

Grand opening of our first ebalta warehouse – later on 3 production halls were inaugurated.

1974

February 18th, 1974: ebalta was founded as a trading enterprise in Rothenburg ob der Tauber.