E-Mobility Casting Resins: Glass fibre reinforced casting resins for the automotive industry

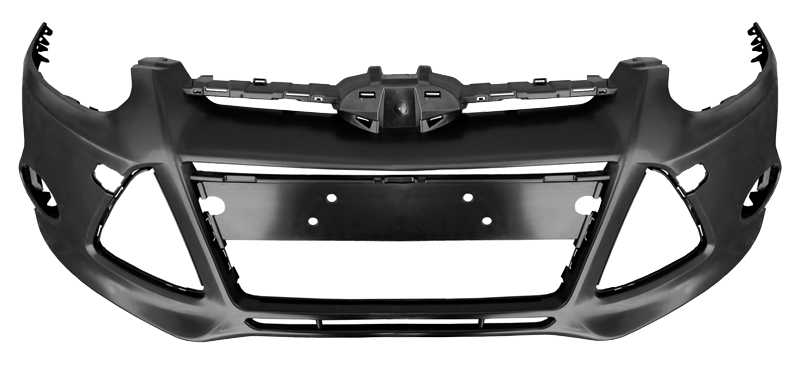

To an ever greater extent, the resins are also used in vehicles as a base material for interior and exterior elements such as bumpers, consoles or armrests; the latter are then often upholstered or painted in a further work step.

Task: Casting resins for application with RIM process

The use of casting resins in these application areas is particularly interesting for manufacturers of special and customised vehicles with fleets of up to 10,000 vehicles. Here, casting resins are supplied for the RIM process (Reaction Injection Moulding). Here, the two liquid components are mixed together in a mixing head and then injected into the corresponding mould, where the material then hardens into its final state.

For suppliers of e-vehicles, ebalta supplies casting resins for both interior and exterior applications, both the corresponding block material in closed form and the liquid resin, which is injected into it and cured before it can then be removed from it as a final product.

Plastic solution: Glass-fibre reinforced casting resin for the medium series

As a casting resin, ebalta’s product MG453 GF (MG = machine casting resin, GF = glass fibre) has recently proved particularly successful in use for the automotive industry. MG453 GF is a high-performance, glass-filled RIM system that is characterised by particularly fast curing times. Because this can speed up the entire production process, it is used here on a large scale for small to medium-sized series production.

One way of supplying glass-fibre reinforced machine casting resin is to use glass-fibre mats, in which the material is added later and thus stabilised. However, the effort required for this is relatively high. At ebalta, the glass fibres are already stirred into the cast resin material before delivery. This results in a specific customization of the material with regard to optimising stiffness and impact strength. The material properties can be customised with regard to their intended use by adding the appropriate proportion of fibres (the products MG453 and MG453 GF can be mixed according to the target specifications).

Both MG453 and MG453 GF are IMDS-registered and thus appropriately stored in the standardised database for material data in the automotive industry. Both casting resins have DIN 75200 approval for automotive interiors and are also flame retardant to FMVSS 302 and are approved for use in both the European automotive industry.